Fr4 Circuit Board Material Properties

Fr4 pcb material properties.

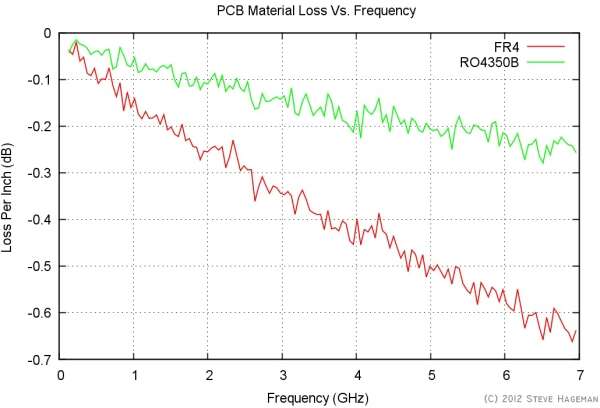

Fr4 circuit board material properties. Fr4 is the backbone material upon which most rigid circuit boards are built. These are commonly referred to as copperclad laminates. However at high frequencies and in environments fr4 is not the best material to use for your boards. However you must consider the effects of transmission line for high track lengths particularly if signal integrity is crucial.

Instead fr4 is a standard defined by the nema li 1 1998 specification and covers a set of properties that the material used needs to comply with. If you happen to work with some high power density designs a high temperature pcb made of fr4 material is the only answer. The boards can be made with four to eight layers of material depending on their specific. Fr4 contains printed circuit board materials suitable for extreme temperature environments.

Boards made from fr4 are strong water resistant and provide good insulation between copper layers that minimizes interference and supports good signal integrity. Printed circuit boards circuit board material. Fr 4 printed circuit boards pcb are fire retardant circuit boards used for electronics. Properties of fr4 circuit board material.

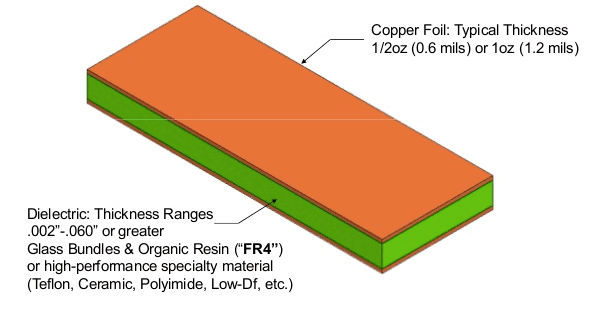

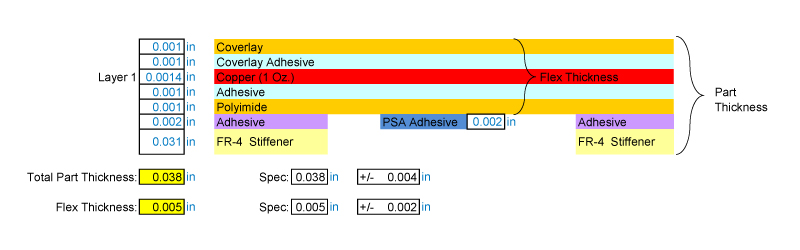

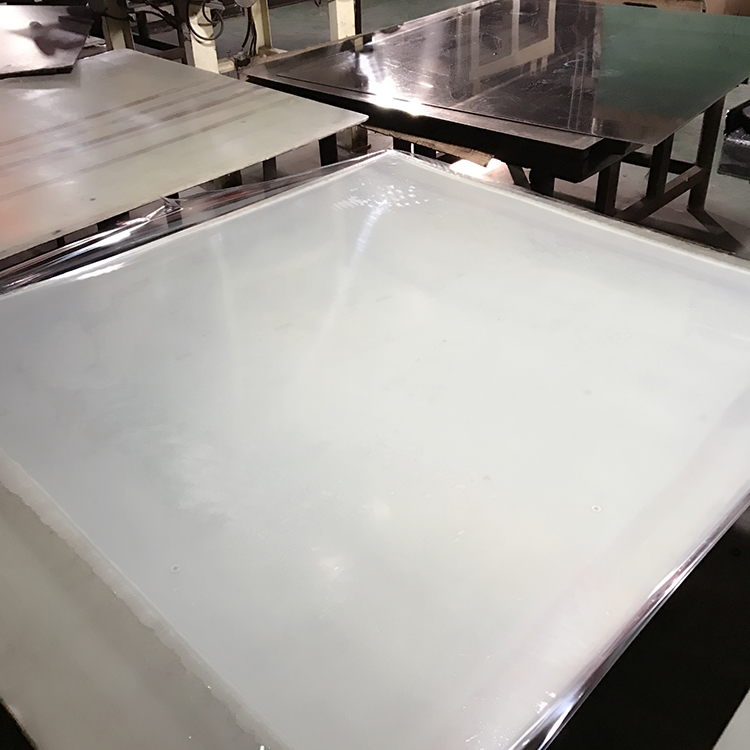

Fr 4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant self extinguishing. About fr4 pcb trace. A thin layer of copper foil is laminated to one or both sides of an fr 4 glass epoxy panel. Fr4 pcb material properties.

Fr4 is rightly the most used material in pcb construction. Fr stands for flame retardant and does not denote that the material complies with the standard ul94v 0 unless testing is performed to ul 94 vertical flame testing in. Most printed circuit boards are manufactured using glass reinforced epoxy laminate as the substrate. It s a misconception to think that fr4 denotes a specific type of material used in pcb manufacturing.

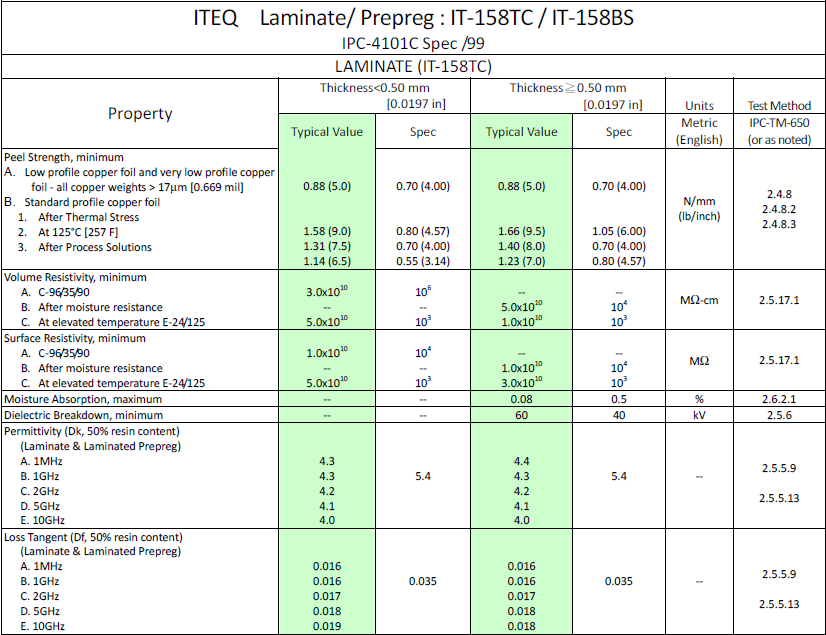

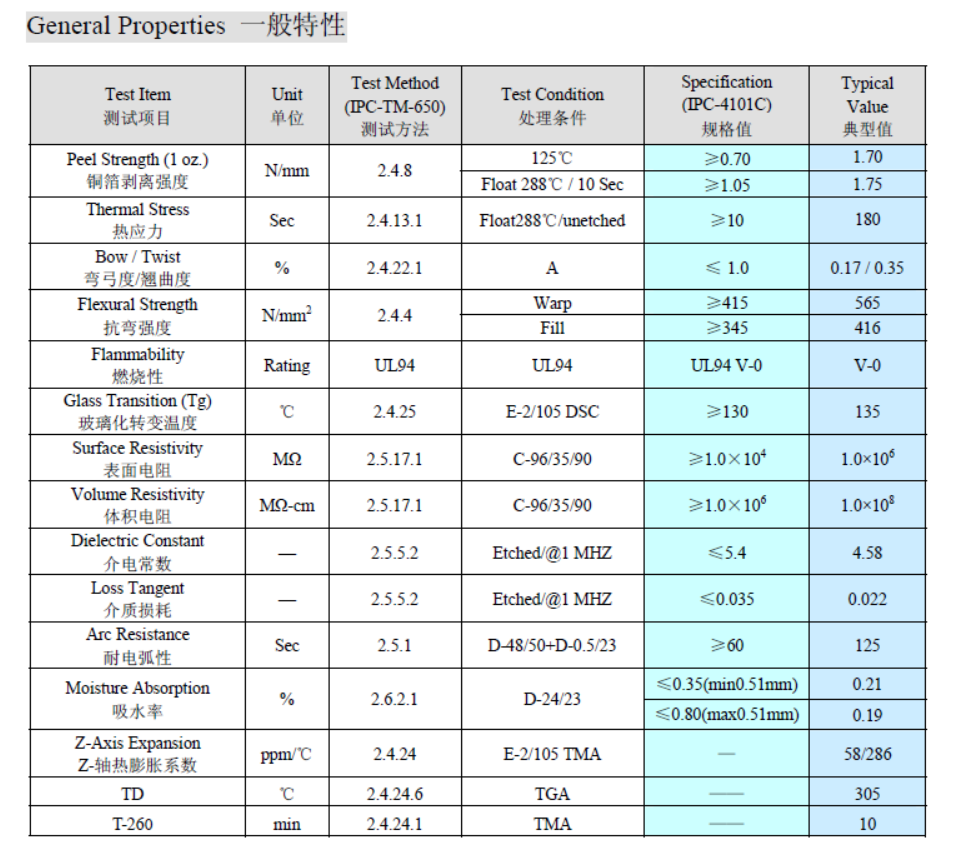

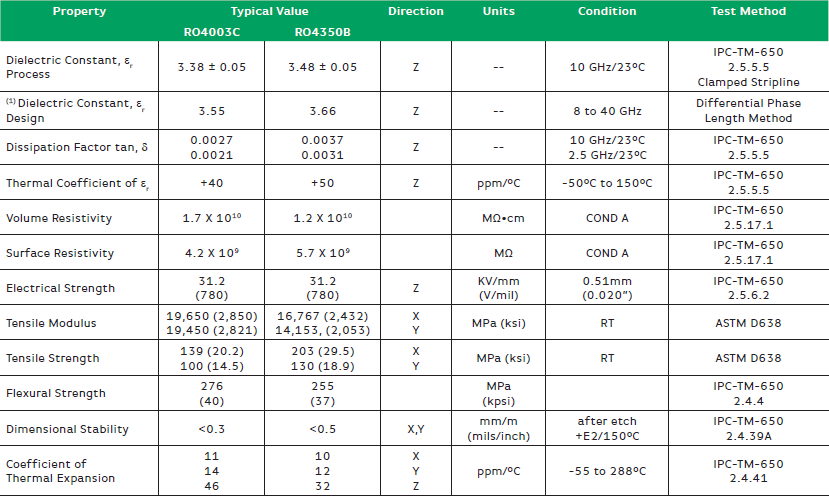

Pcbway jan 20 2014 3011 views 0 comments posted in engineering technical. Raw material technical datasheet property item i physical property density water absoption flammability class thermal property chemical property tensile strength vertical flexture strength vertical compression strength parellel shearing strength parellel impact strength bonding strength elastic modulus hardness rockwell hardness shore d. Products that experience high thermal loads or working in the range of 130 degrees celsius are good with fr4 material. Fr 4 is the primary insulating backbone upon which the vast majority of rigid printed circuit boards pcbs are produced.

While there are a wide variety of laminates available on the market fr 4 is both versatile and well accepted as a standard material for pcb manufacture. Fr 4 or fr4 is a nema grade designation for glass reinforced epoxy laminate material.